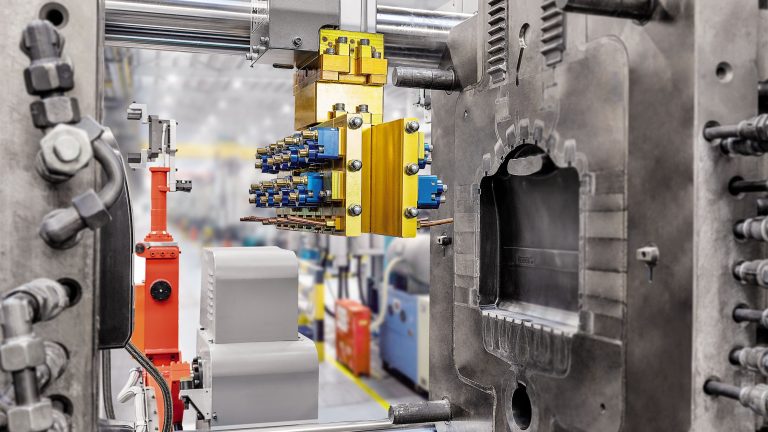

Amidst the busy schedule of day-to-day life, at a certain point, one seems to wonder about the complexity of the things around and how they are manufactured. Products such as cars, jets, rockets, and even small complex metal parts and components. These are so common for people today but were once considered a very tough piece of engineering to replicate and mass produce. Complex parts of heavy machinery or even small complex parts of different types of equipment require great precision and detailing, while production was once very difficult and costly to achieve. This problem was solved by the cold chamber pressure die casting technique.

This method is used in the manufacturing of complex designs of metal today. It involves melting metal at very high temperatures in a furnace separate from the casting machine and then forcefully sealing it inside a metal cavity under extremely high pressure. This casting technique has equipped humankind with the power to manufacture complex metal shapes and designs with great precision and detail at a very low per-unit cost. Making it affordable to a majority of the population. This process is fully automated, unlike other casting techniques. The metal injection under high pressure lowers the loss of liquid metal while filling cavities, thus making it a more efficient and reliable process.

Types of Pressure Die Casting

There are two types of pressure casting techniques that can be used to produce different types of metal parts or components. The two said techniques are:

- Cold chamber pressure die casting

- hot chamber pressure die casting

The only major difference between the two techniques is how metal is molten and filled inside the cavity. In the cold chamber process, metal is melted and liquified in a furnace separate from the cavity. After being molten, it is transferred to the cavity and injected under high pressure. At the same time, the hot chamber process involves the melting and liquification of metal in the casting machine itself rather than a separate furnace.

Conclusion

The pressure die casting technique allows the production of complex metal shapes with great ease and precision while also being economically efficient. Though both the hot chamber and cold chamber process are considered under pressure to die casting technique, they are used to produce different metal parts. The hot chamber process is limited to producing parts from metals with a low melting point, like zinc and magnesium alloys. In contrast, the cold chamber process is used to produce parts of metals having even higher melting points.